HIGH-FREQUENCY TEMPERING MACHINE

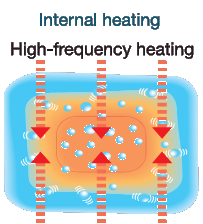

Thawing uniform even thick material. High-frequency tempering by internal heating.

TEMPERTRON

About Tempertron

High-frequency electric fields induce molecular motion within frozen materials, causing the material to generate heat internally. This process allows for uniform thawing throughout the entire product without excessive melting at the surface. As a result, there is minimal drip loss, making it possible to use fresh frozen materials more effectively. This method effectively thaws frozen bricks of meat, such as beef, chicken, and fish, from -20°C to -1 to -5°C using internal heating. The thawing process is rapid, taking only 5 to 30 minutes, resulting in a uniform temperature throughout the entire brick. This ensures that the material is at an optimal temperature for the next processing step.

Different Types of Tempering Machine

Batch Type (small CAPACITY)

BATCH Type (medium CAPACITY)

Comparison of conventional and high frequency thawing

Conventional thawing relies on heat conduction from the exterior, which results in a prolonged thawing process. As the surface ice melts and turns to water, the heat conduction efficiency decreases to one-quarter of that of ice. This leads to reduced efficiency in heat transfer and creates an imbalance between the thawing of the surface and the center. While High-frequency energy can penetrate deeply into the material, generating heat internally. This results in significantly faster thawing times and a smaller temperature difference between the surface and center compared to external heating. The internal heating effectively addresses quality issues.

Features / Benefits of high frequency thawing

-

Food can be thawed quickly in 5 to 30 minutes

-

Even thick frozen products can be thawed evenly

-

Drip loss is minimized to improve yield

-

Continuous processing from frozen storage through to thawing and other post-processes is possible

-

Products can be thawed as they are, in cardboard boxes and vacuum packs.

-

You can work on dry floors and in amenable environment as no water is used at all

-

Presetting thawing conditions allows anybody to thaw products to consistently high quality

-

There is no fear of bacterial contamination as no water is used at all.

-

Continuous processing saves labor, Also, thawing space can be drastically reduced.